The horizontal, side entry agitators are usually used in big basins/ containers, with roof construction’s stiffness not allowing the installation usage of a vertical agitators. The side entry solution ensures that you can prevent expensive roof reinforcements.

Disadvantages compared to vertical agitators:

To achieve a comparable flow rate to the vertical top entry agitator, you have to install a considerable higher engine power, caused by the impeller sizing limits on side entry agitators.

Shut off - Device

The tank Shut-off device is an equipment for the horizontal side entry agitator. The Shut-Off device allows the customer to remove/ change the gearbox, the lantern or the mechanical seal without emptying the tank.

The special closing mechanism consists of a shaft collar, which is pushed into the prepared bore for the shaft inlet. The collar shuts the gap between shaft and flange by closing it safely.

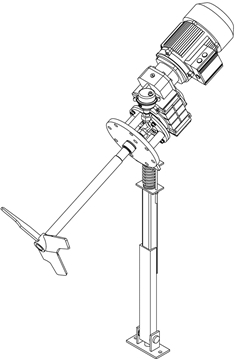

FSS-4-5,5 with lubricate mechanical seal, forced venting function including compensation support

The support column

The support column for side entry agitators will stabilize the unit, if the tank construction and/ or the tank’s mounting stud is not strong enough.

The column will absorb the vibrations, which can occur by weak construction and also if the agitator’s speed coincide with the critical vibration frequency of the construction tank-stud (resonance).

This compensator column is constructed with the benefit of compensating the mounting studs motions (horizontal and vertical). The stud can be moved by e.g. Filling/ Emptying of the tank, surrounding and medium temperature changes.