Our company produces agitators according to the explosion protection directive 2014/34/EU [formerly 94/9/EG] successfully since 2002. This guideline specifies in which way machines or a protective system have to be constructed to meet the safety requirements, which arise from a hazardous explosive atmosphere. [0,1,2 gas and 20,21,22 dust]. The operator of a plant with areas having an hazardous explosive atmosphere must also take into consideration the directive 99/92/EC. This directive specifies/ organize the requirements for workers/ work in such areas (includes the specification of zones, the demand of an Explosionproofdocument,…).

We are producing agitators, which can be used in areas exposed to explosion hazards, due of their different kinds of zone separation and drive concepts. Depending on the given general conditions, we are choosing a proper agitator for you.

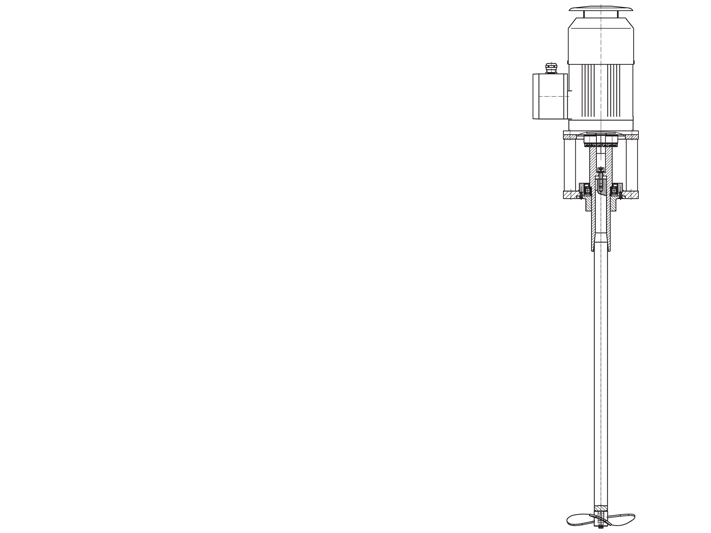

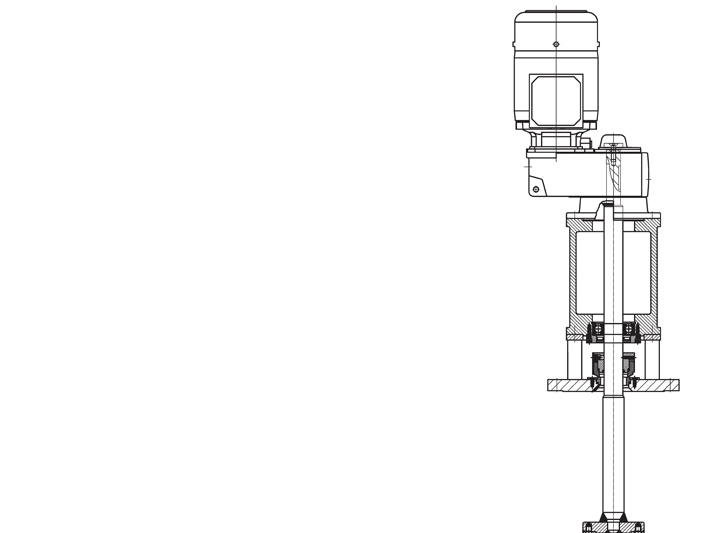

II 1/2G FLDS-3-3,6 Exd

Zone separation: 0 and 1

Drive: IEC-normmotor

Gear: parallel shaft gear unit

Sealing: mechanical seal

Impeller: AD

Accessories: barrier fluid system

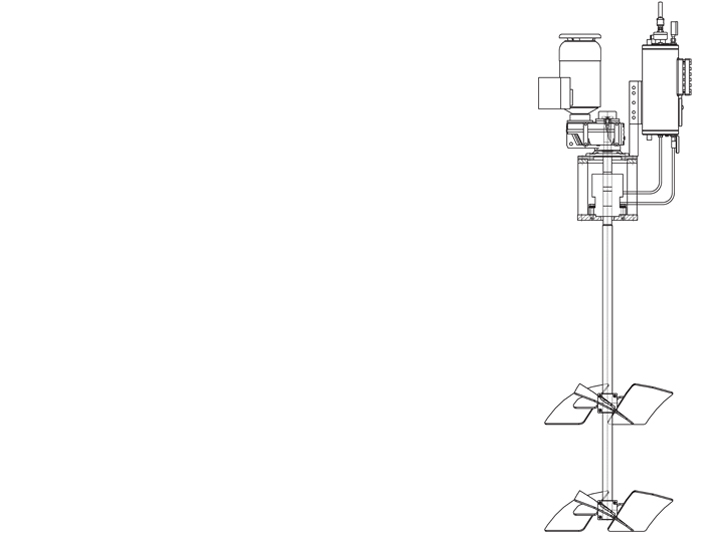

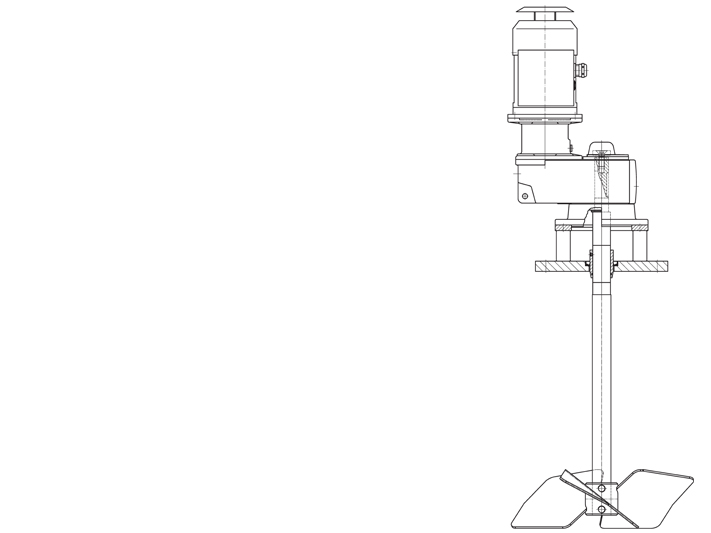

II 3G GQ-3-1,1 A

Hazardous explosive atmosphere: 2

Drive: pneumatic motor

Gear: helical

Impeller: PJ

Accessories: large silencer, safety flange,

quick change coupling

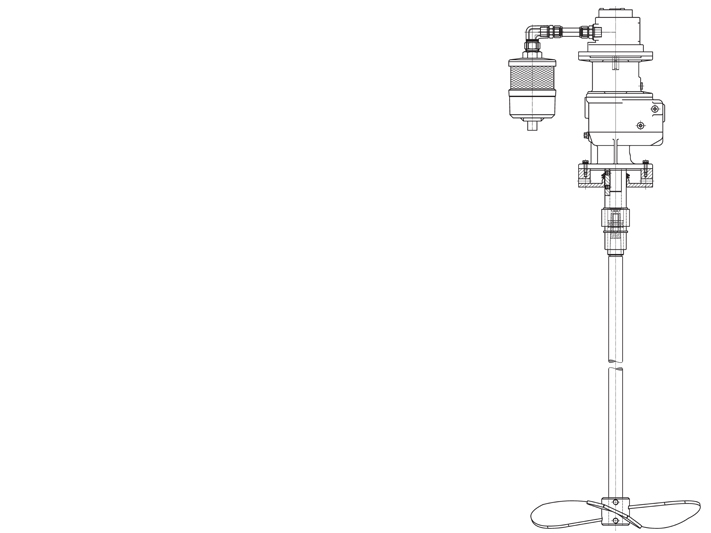

II 3G DQ-1-0,55 Exd

Hazardous explosive atmosphere: 2

Drive: IEC-normmotor

Impeller: L-Impeller

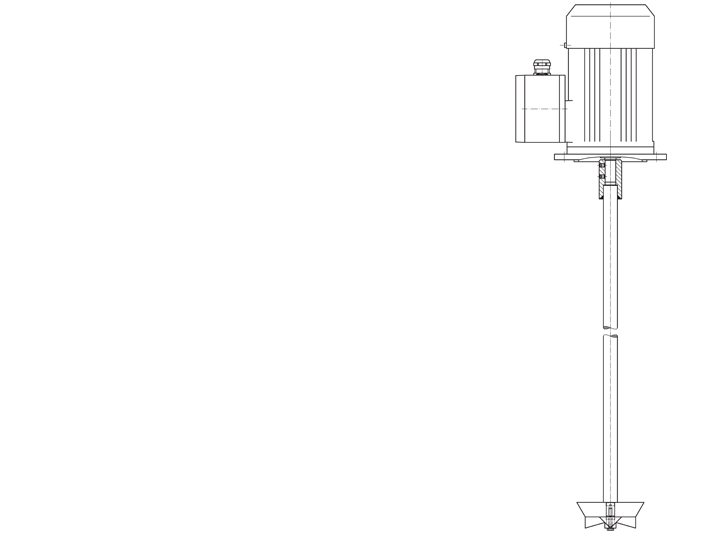

II 1/2G NFLS-2-1,1 Exd

Zone separation: 0 and 1

Drive: IEC-normotor

Gear: parallel shatf gear unit

Sealing: dry running mechanical seal

Accessories: bearing lantern, flange coupling

II 1/2G FD-3-0,55Exd

Zone separation: 0 and 1

Drive: IEC-normotor

Gear: parallel shatf gear unit

Sealing: radial shaft seal

Impeller: AD

Accessories: shaft protection sleev

II 1/2D OFX-2-0,75 Exd

Zone separation: 0 and 1

Drive: IEC-normotor

Sealing: gap criterion

Impeller: PJ

Accessories: OF mixer shaft