options

Stuffing box

| operational conditions | ||

| – pressure: | standard: low / high pressure up to 6 bar special design: up to 40bar | |

| – temperature: | approx. 0°….200°C, above with liquid cooling | |

| material: | housing: carbon steel / stainless steel; packing: PTFE silk, graphite fiber, … | |

| The stuffing box is used to protect the mechanical drive against steam and as a splashing barriere. This gasket can also seal “higher” pressure, however, compulsive and continuous leakage cannot be avoided. This seal requires continuous control and service. In many cases it is a favorable and robust solution for blocking pressure. | ||

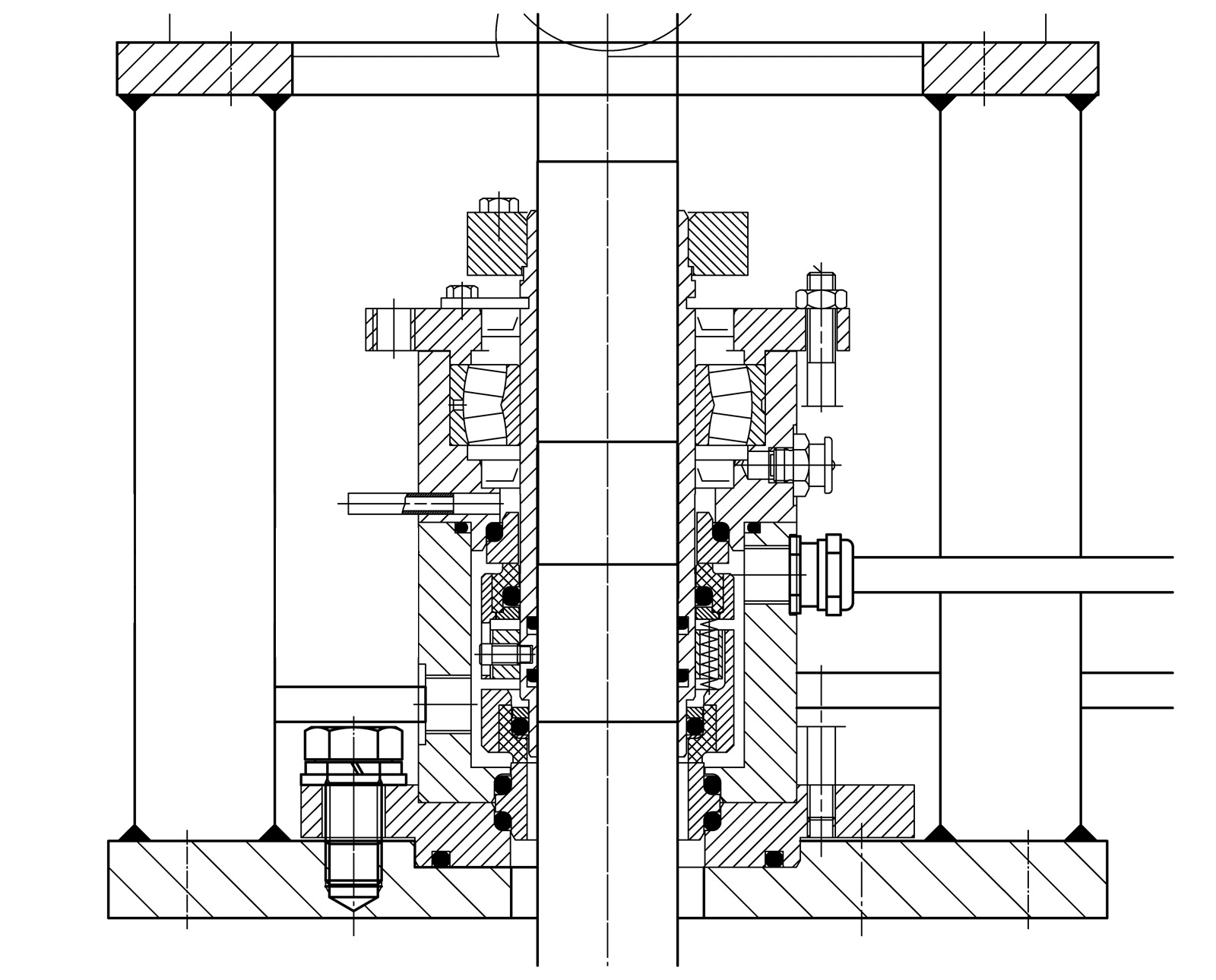

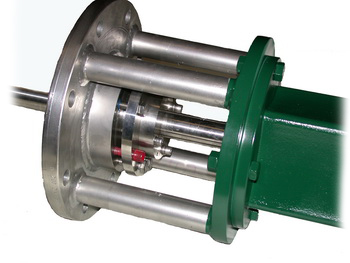

Mechanical seal

| operational conditions | ||

| – pressure: | standard: low / high pressure up to 12 bar (1200 kPa)

special design / double-acting mechanical seal: up to 100bar including cooling and lubrication |

|

| – temperature: | approx. 0°….200°C, above with cooling and lubrication | |

| material: | housing: carbon steel / stainless steell: Viton, NBR, PTFE, PFA,…. seal material: carbon/ ceramic/ chrome/ WoC/ SiC / …. | |

| The axial face seal is used to seal the shaft inlet against pressure. Available in many variations (single-acting seal, double-acting seal, dry-running, coaxial , tandem, back to back….). This gasket is the standard in the most industrial sectors for application in pressure vessel. |

||

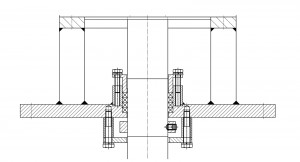

Shut off

| operational conditions | |

| Supplement to the mechanical seal for side/bottom/ top entry agitator installation, if during the seal/ drive change the pressure / the medium must be held in the vessel. | |

| This device allows not only the change of the drive/gearbox for service and repair work, but also exchanging the side entry seal without emtying the tank.

The special locking system exists of a metallic cylinder on the shaft, which is pushed in the special shaft inlet of the laterne flange to close the gap between shaft and flange. |

|

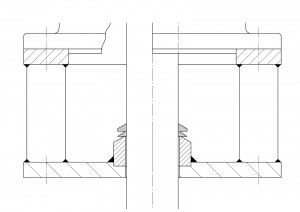

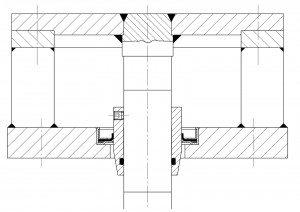

Radial shaft seal

| operational conditions | ||

| – pressure: | depending on the shaft speed; pressure up to 10 bar special up to 25 bar | |

| – temperature: | ca. 0°….100°C special up to 260°C | |

| material: | special material PTFE based | |

| The radial shaft seal is used to seal the shaft inlet against pressure. This gasket has the advantage of small instalation dimensions compared to the mechanical seal. But the seal’s wear is higher. To protect the mixing shaft against “shrink” a hardened shaft protection sleeve should be installed as seen in the drawing above. | ||

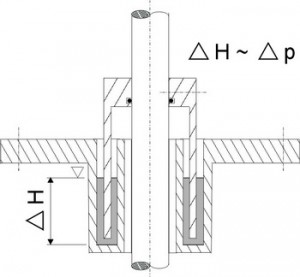

Labyrinth seal

| operational conditions | ||

| – pressure: | marginal pressure difference of mbar | |

| – temperature: | ca. 10°….50°C, | |

| material: | water / oil | |

| The Labyrinth seal is used to seal the shaft inlet against low pressure fluctuations, often this seal is used as an odour barrier. That’s why the main area of application is also in sewage treatment plants. The seal requires continuous control, can be also equipped with a liquid level switch. | ||